Mining minerals has always been an arduous forceful task, both underground and on the surface.

Noise is now, however, a generic hazard common to all commodities and, to a greater or lesser extent, all operations within mining.

One out of every four mine workers has a hearing problem. Even worse, four out of five mine workers have a hearing impairment when they reach mid-60’s retirement age.

Hazardous noise is the primary culprit – 76% of mine workers are exposed to hazardous noise, the highest prevalence of all major industries.

Table of Contents

- What are Sound and Noise?

- Why is Noise an Important Workplace Hazard?

- Mining Equipment and its impact on Mine Workers

- Methods of Controlling Noise Exposure Among Mine Workers

- The Severity of Noise-Induced Hearing Loss Among Mine Workers

- I think I have Work-Related Hearing Loss, what do I do?

- Sources

What are Sound and Noise?

Sound is what we hear, and noise is considered an unwanted sound. Sound is produced by vibrating objects and reaches the listener’s ears as waves in the air or other media.

When an object vibrates, it causes slight changes in air pressure. These air pressure changes travel as waves through the air and produce sound.

To illustrate, imagine striking a drum surface with a stick. The drum surface vibrates back and forth. As it moves forward, it pushes the air in contact with the surface. This creates a positive (higher) pressure by compressing the air, and when the surface moves in the opposite direction, it creates a negative (lower) pressure by decompressing the air. As the drum surface vibrates, it creates alternating regions of higher and lower air pressure. These pressure variations travel through the air as sound waves.

The hearing mechanism of the ear senses the sound waves and converts them into information which it relays to the brain. The brain interprets the information as sound. Even very loud sounds produce pressure fluctuations which are extremely small (1 in 10,000) compared to ambient air pressure.

Read More: Ear damage from loud noise – Noise-Induced Hearing Loss and Tinnitus >

The hearing mechanism in the ear is sensitive enough to detect even small pressure waves. It is also very delicate: this is why loud sounds may damage hearing.

Why is Noise an Important Workplace Hazard?

Noise is one of the most common occupational health hazards. In heavy industrial and manufacturing environments.

Permanent hearing loss is the main health concern. Additional problems that may occur are annoyance, stress, and interference with speech communication.

Read More: Noise Hazards at the Workplace >

To prevent adverse outcomes of noise exposure, noise levels should be reduced to acceptable levels. The best method of noise reduction is to use engineering modifications to the noise source itself, or to the workplace environment.

Where technology cannot adequately control the problem, personal hearing protection (such as earmuffs or plugs) can be used.

Personal protection, however, should be considered as an interim measure while other means of reducing workplace noise are being explored and implemented.

Mining Equipment and its impact on Mine Workers

National Institute for Occupational Safety & Health estimates that 80% of US miners go to work in an environment where the Time-Weighted Average (TWA) exceeds 85 dB and that 25% of these are exposed to a TWA noise level that exceeds 90 dB.

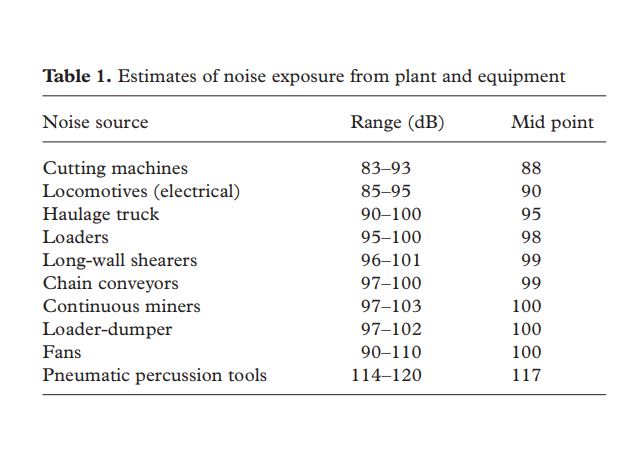

Estimates of the noise exposure from plants and equipment are shown in Table 1.

Table 1

One of the first mining operations to become mechanized was that of shot-holes, and the pneumatic percussion drill is still the major noise hazard in mining today.

The impact from the drill bit, mechanical vibration from the drill casing, and impulse noise from the exhaust generates the noise.

The equipment may be either hand-held and used in the maintenance of roadways to keep them open by “ripping” the roof, or man-handleable, such as the drills used for placing roof bolts.

Read More: Occupational Noise Exposure Among Road Construction Workers >

Ancillary equipment is also noisy – this includes fans and blowers for mines ventilation, where the noise comes from structural resonance and energy from the aerodynamic flow.

The extractive equipment itself, either continuous miners or longwall shearers, produces continuous noise from the power pack and transmission (gear) system and impact noise from the cutting head and the associated armored conveyor system.

Transport and mechanical handling noise come from diesel-powered load handlers and materials or man-carrying haulage equipment.

The noise sources are engine, transmission, and exhaust, while diesel-powered locomotives and man-riding cars have additional components from wheel-track impulse noise and structural vibration.

Conveyor systems, apart from the drives, should not be excessively noisy if properly maintained.

Blasting underground differs from that on the surface, being influenced by mine geometry, openings, and friction from wall roughness. As with other impulsive exposures, the cumulative effect on mine workers is unclear.

Methods of Controlling Noise Exposure Among Mine Workers

The hierarchy of control needs to be examined carefully in mining because noise elimination techniques have been evolving over the past few decades.

Management needs to be aware of these factors and adopt the principle of “buying quietly”. Replacing worn components, especially in vibratory equipment, and having good maintenance schedules may also dramatically reduce noise.

Some of the changes involve both new technologies and changed working practices – for example, the development of tele-controls for pneumatic percussion drills have allowed the separation of man and machine.

Hearing Protective Devices (HPDs) are often used, and misused, in the mining environment. The danger is that the protection factor of hearing protection degrades very rapidly with poor compliance or ineffective fit, and so they often do not control the noise hazard.

The compliance issues arise because HPDs are not particularly comfortable and interfere with communication, so if noise is intermittent—always a problem in mining and they are unlikely to be worn or may frequently be taken off.

Read More: Hearing Protection At Work >

For the sake of comfort and communication, it is therefore essential that the HPD is matched to both the individual and the noise environment in which they work.

Earmuffs are the best technical choice as they give better sound attenuation than earplugs. Paradoxically, plugs seem to perform better, the explanation being that if noise is intermittent, it is considerably easier to remove muffs

Source: Pexels

The Severity of Noise-Induced Hearing Loss Among Mine Workers

Noise exposure and noise-induced hearing loss are still prevalent in the mining industry.

There is no doubt that the majority of miners are exposed to hazardous levels of noise, most exceeding 85 dB, and some the peak exposure standard of 140 dB.

If you are a miner and have a loss of hearing, you may experience these symptoms:

- Difficulty hearing warning signals

- Difficulty hearing what someone is saying

- Accidents

- Ringing or buzzing in your ears

- After you leave a noisy area, your hearing may seem dull or muffled

- Headaches

- Tiredness

- Stress

Most of the risk comes from the need to use heavy machinery underground, but careful design and new technology and materials can be

used to minimize this.

Read More: Can hearing loss cause other health problems? >

Some degree of residual hearing protection may well be required, but this should be part of a well-designed hearing protection program.

I think I have Work-Related Hearing Loss, what do I do?

If you think you may have noise-induced hearing loss, you should see an audiologist. Audiologists are hearing professionals and are able to perform tests to check your hearing. Talk to your doctor about your hearing and ask to see an audiologist.

Read More: All About Workers’ Compensation >

If you have had a hearing test and/or have been diagnosed with hearing loss that you feel may be caused by working in one or more noisy workplaces you should contact us here at Johnson Law Offices and file a claim for noise-induced hearing loss.

Sources

- https://watermark.silverchair.com/kqh075.pdf?token=AQECAHi208BE49Ooan9kkhW

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7136819/

- https://journals.sagepub.com/doi/abs/10.1177/0957456518781860?journalCode=nvwa

Contact Us

If you, or anyone you know, worked in noise and suffers from hearing loss, please do not hesitate to contact us.

Contact Us